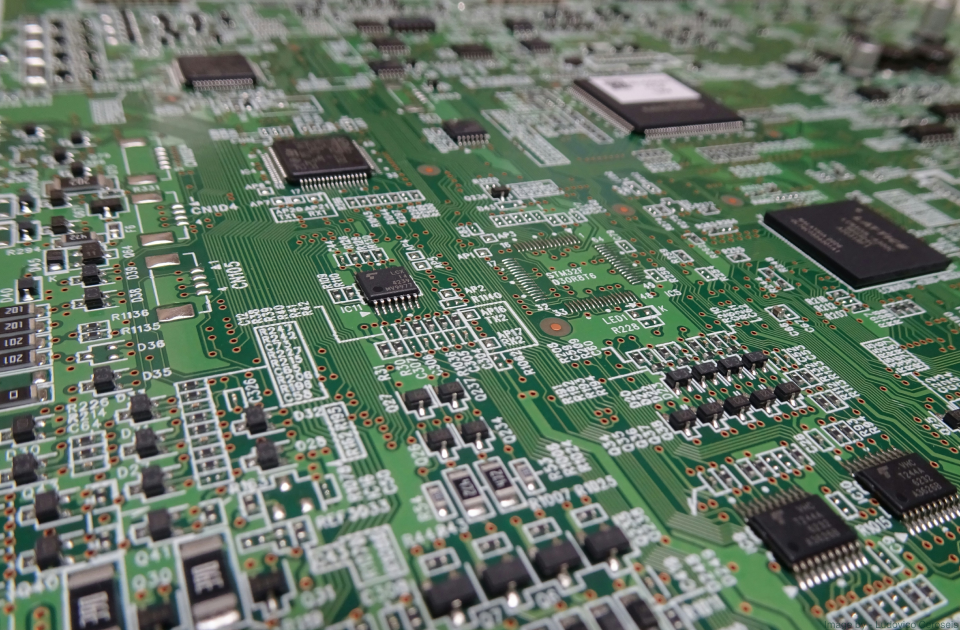

PCB Assembly

High-precision SMT & THT PCB assembly for prototypes, small batches, and full-scale production.

What We Do?

We deliver reliable and high-quality PCB assembly services designed for companies that need accuracy, speed, and consistent performance. Using advanced SMT equipment, strict quality checks, and skilled technicians, we support everything from prototype boards to mass-manufactured assemblies.

SMT & Surface Mount Assembly

We assemble SMD components using modern pick-and-place machines, ensuring high precision, stable performance, and compatibility with complex multilayer PCBs.

Through-Hole (THT) Assembly

Reliable manual and wave-soldered through-hole assembly for connectors, large components, and parts requiring strong mechanical stability.

Mixed Technology PCB Assembly

Combining SMT and THT processes to handle hybrid boards used in industrial electronics, power modules, automation devices, and custom applications.

Prototype & Low-Volume Manufacturing

Fast and flexible prototype assembly with quick turnaround times, helping you validate and refine your product before full-scale production.

How We Do It?

Our assembly workflow is designed for precision, repeatability, and efficient production. Every PCB passes through standardized steps that ensure optimal quality at each stage.

File Review & BOM Verification

We analyze your Gerber files, BOM, pick-and-place data, and assembly notes to ensure manufacturability and reduce potential errors.

Component Sourcing & Preparation

Components are sourced from trusted suppliers, inspected, and prepared for assembly to maintain consistent quality and traceability.

SMT/THT Assembly & Soldering

Boards move through automated SMT placement, reflow soldering, or wave soldering for THT components—followed by manual touch-ups if required.

Inspection, Testing & Delivery

Every PCB undergoes visual inspection, AOI (if applicable), and functionality checks before being securely packed for delivery.

Let’s Talk

Need a reliable partner for your PCB assembly needs?

Whether you are building your first prototype or scaling a commercial product, we provide the expertise, equipment, and support needed to assemble PCBs with accuracy and consistency. Reach out to discuss your project or request a quote—we’re ready to help.

Contact Us